Overhead Chain conveyor Systems china Conveyors Systems manufacturer

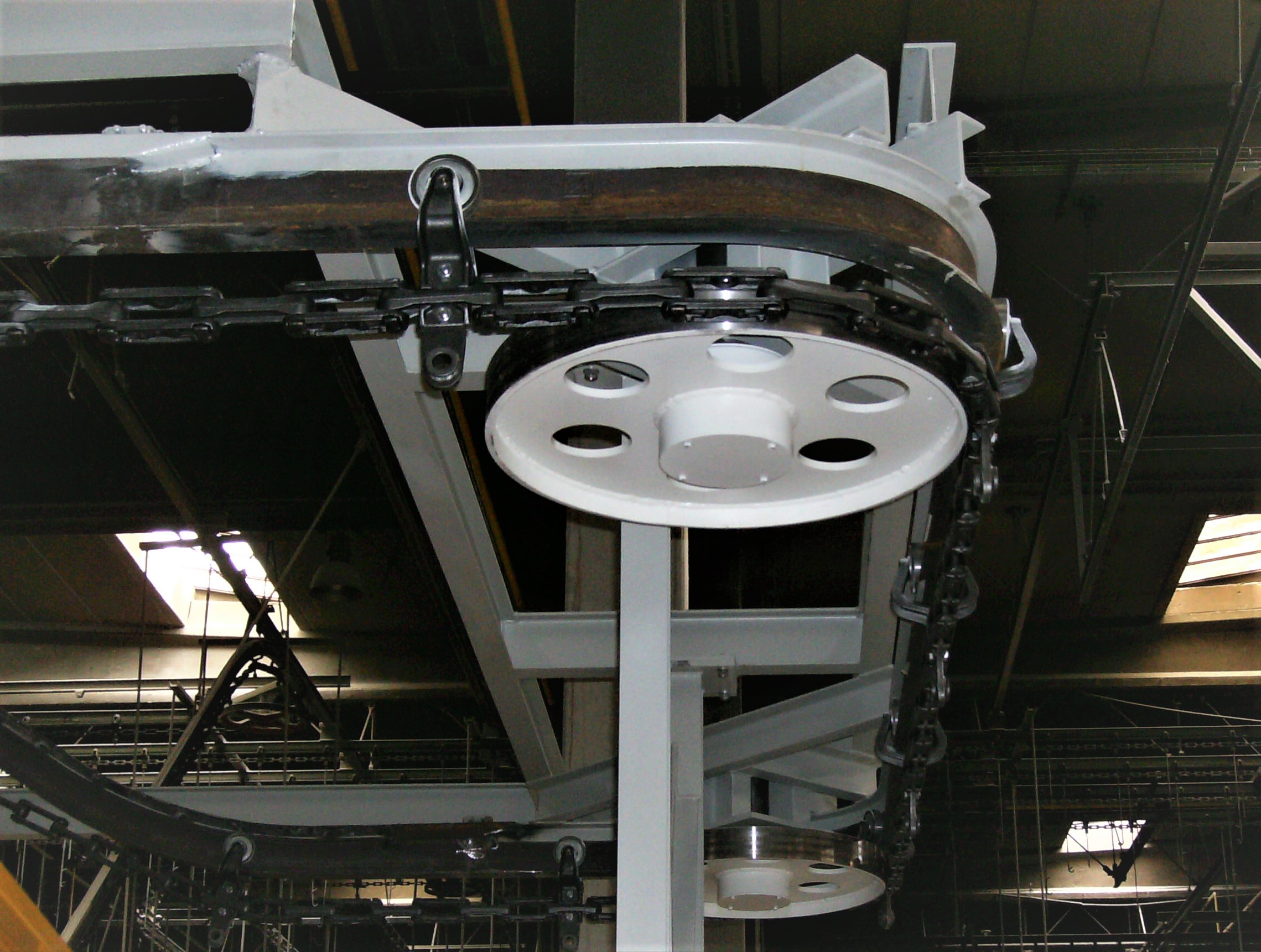

I-beam overhead conveyors are open-track conveyors where a chain rides on an i-shaped metal beam that is suspended horizontally from the ceiling. Items are transported on pendants or trolleys that hang down from the ibeam and are propelled by the chain.

.jpeg?itok=voGfVuuI)

K8 Overhead Chain Conveyor at Unibike Portugal Railtechniek van

The overhead chain conveyor is a cost-effective solution wherever large quantities of material to be transported are to be transported at a constant speed. The classic system of overhead conveyor technology is particularly suitable for use in extreme environmental conditions and in enclosed spaces.

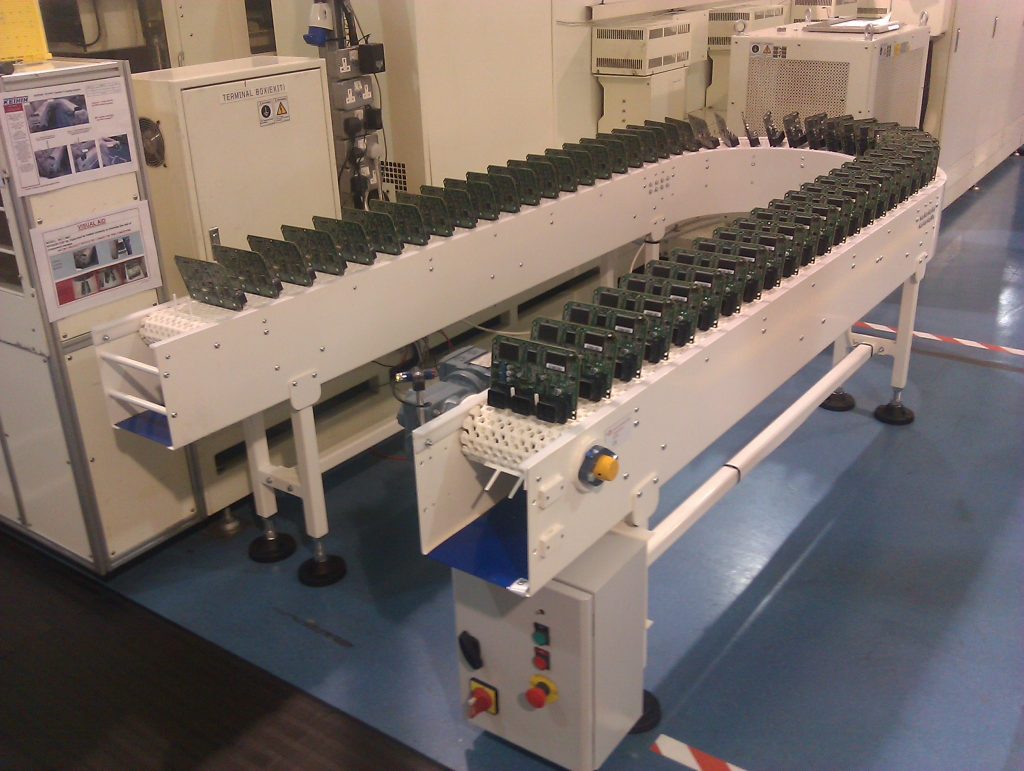

Automatic Stainless Steel Overhead Chain Conveyor, Length 4060 feet

The Original Bridgeveyor™ Overhead Conveyor System Home / Systems Why Choose The Bridgeveyor™ C-250™? It's a Smart Investment From small workshops to the largest manufacturing and warehousing facilities, you need to know that the overhead conveyor chain system you choose makes the most sense for your business goals and bottom line.

Overhead Chain Conveyors Prestige Conveyors Ltd

Overhead conveyors are what people are generally thinking about when they hear the word "conveyor". One of the most common types of conveyor, an overhead conveyor is generally used in a production facility to move parts from one location to another. They take advantage of the generally unused vertical space above the working area.

Optieng Overhead Conveyor Systems

Wear Gauge for Grade 80 and Grade 100 Chain. Gauge measures the maximum allowable wear tolerances on links of Grade 80 and Grade 100 steel chain, as required by OSHA. If the gauge can be inserted over any part of the link, the chain should be taken out of service. Choose from our selection of conveyor chain belting, sprockets for conveyor chain.

Heavy Duty Overhead Conveyor Enclosed Track Chain Conveyor

Chainveyor® overhead conveyor systems offer an innovative solution that provides a low cost, light-duty option to meet a diverse range of material handling needs. If the products on your conveyor line weighs 400 pounds or less, don't pay more for heavy-duty when a light-duty conveyor option costs a lot less.

Optieng Overhead Conveyor Systems

Overhead conveyors include track, brackets, carriers, chains, and other components that are used to create an unpowered or powered overhead conveyor line. Items are suspended from the conveyor as they move down the line, making overhead conveyors ideal for transporting products that are too large or irregularly shaped to be carried on a.

Overhead Conveyors Monorail Conveyor Systems Overhead Systems

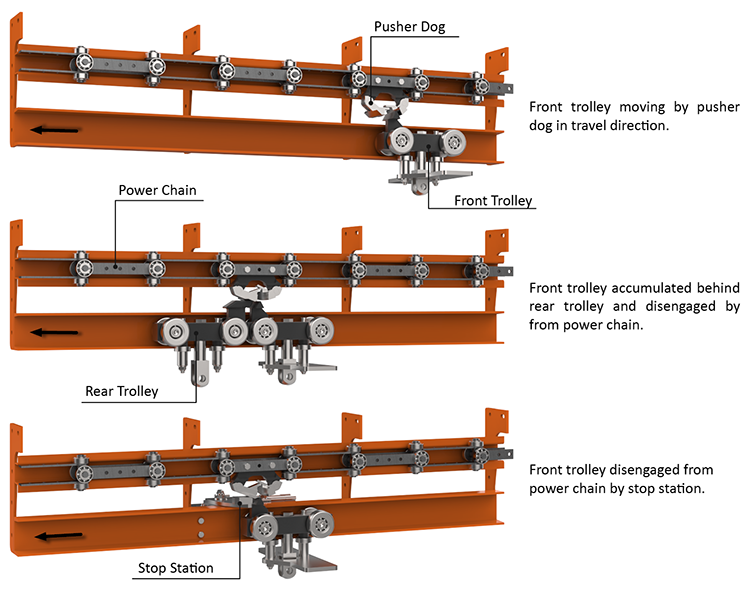

Overhead Conveyors are of three basic types: Free Systems with hand pushed trolleys available with a complete line of curves, brackets, switches, turntables, crossovers, lowerators, etc Power Systems with chain, drive (s) and a complete line of horizontal and vertical curves, take-ups, attachments, load bars, safety devices, etc

Optieng Overhead Conveyor Systems

This overhead conveyor chain has 6" pendant centers for more hanging points and 60 pound per foot load capacity. Series 200 Stainless steel enclosed track horizontal turns and vertical curves offer ultimate hardness and corrosion resistance. The tight enclosed track turn radius increases efficiency and saves floor space.

Drop Chain for overhead conveyor X348 X458 X678 698 ZMIE chain

W.M. Kelley offers the unique Chainveyor® overhead conveyor, a product line that has been solving materials handling problems since 1952. Our Series 200 and Series 300 Enclosed Track Overhead Conveyor provide a very economical light to medium-duty conveyor that is ideal for: Paint lines Carton supply to order pickers

Overhead Conveyors Types, how they work, benefits and uses

Overhead conveyor systems, design, and high-performance chain from Richards-Wilcox increase efficiency and automate processes for your company. Call today!

Powered overhead conveyors (Automationandmaterialshandling Solutions

STANDARD OVERHEAD CONVEYOR CATALOG Catalog and Design Guide. Standard Conveyor Catalog 1 Toll Free: 888-852-1020. rwconveyor.com 2. two chains attached to the frog plates through a pulley system Pulling one chain shifts the switch . to the left-hand position; pulling the other chain

How does a Power and Free Overhead Conveyor work? Railtechniek van

Overhead Trolley Conveyors | McMaster-Carr (562) 692-5911 Email Us Log in Order Order History Filter by Component Bracket Carrier Chain Track Trolley System of Measurement Inch Weight Capacity Less than 1,000 lb. 1,000 lb. to 9,999 lb. Material Steel Bracket Type Joint Support Height 1 1/2" 2 3/4" 3" 4" 4 1/4" 4 7/16" 4 1/2" 4 15/16" 5 5/8" 6 1/16"

Overhead conveyors OHC Systems

Take-up sections allow for chain oiling, stretch maintenance and tension; Simple machines with 99.9% uptime; Benefits of overhead trolly conveyor. The benefits of overhead conveyors are vast but are also dependent on a specific operation. Reduces forklift traffic, labor, floorspace, and machines; Allows for easy inspection of production line goods

Silver And Blue Mild Steel Overhead Chain Conveyor, Capacity 100150

The PAC-LINE™ is a medium-capacity, enclosed track overhead monorail conveyor designed for maximum conveying flexibility in small spaces. 50 lbs. per pendant. Cross Track Conveyor The PAC-MAX™ is a heavy-duty enclosed track conveyor that features a unique cross "+" shaped track for exceptional load stability. 220 lbs. per trolley.

Overhead Chain Conveyor at Rs 28000/meter Material Handling Conveyor

Overhead conveyors and towline floor conveyors designed for wood shops and woodworking applications such as product assembly lines, parts buffers, stain and paint finishing. PACLINE designs, manufactures and installs overhead conveyor systems for a wide range of material handling solutions. Call for a quote today 1-800-955-8860!